LoRaWAN Irrigation Control Systems

Why Automate Irrigation

Most irrigation runs on fixed schedules. "4 hours every 3 days" regardless of whether it rained yesterday or the soil is already saturated. It's simple to program but wasteful.

I've measured this: soil moisture-based control cuts water use by 30-50% compared to fixed schedules. Crops get water when they actually need it, not when the timer says so. Plants do better, water bills drop, and you stop irrigating during rainstorms. Simple upgrade, significant impact.

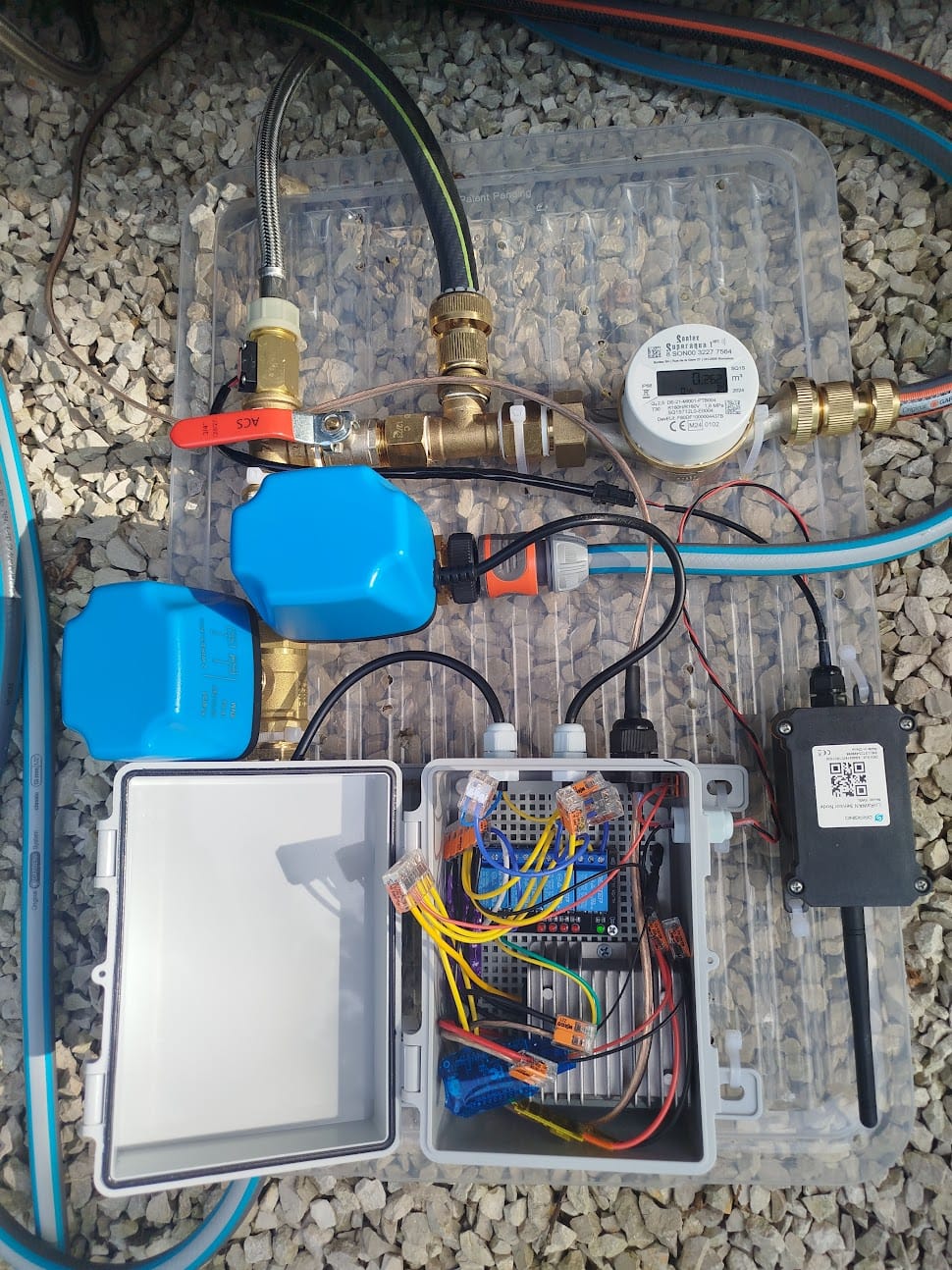

System Components

Sensors:

Soil moisture probes installed at root depth measure actual water availability. Capacitive or TDR sensors provide volumetric water content readings that drive irrigation decisions. Temperature sensors (both soil and air) feed evapotranspiration calculations, predicting crop water demand. Rain gauges skip scheduled irrigation after precipitation, preventing water waste. Soil EC sensors add salinity monitoring where salt accumulation threatens crops.

Controllers:

LoRaWAN solenoid valve actuators operating on 12V or 24V control water flow to irrigation zones. Pulse counters meter actual flow, detecting leaks, broken pipes, or clogged emitters. Battery or solar power enables autonomous operation in fields lacking grid infrastructure. Latching solenoid valves minimize power consumption, extending deployment duration between maintenance.

Network:

LoRaWAN gateways provide wireless coverage across agricultural terrain without cellular infrastructure. Network servers (ChirpStack, The Things Network, or commercial platforms) handle device management and data routing. InfluxDB stores time-series sensor data, Grafana visualizes it, and custom logic engines implement automated control rules based on sensor readings and crop requirements.

Control Strategies

Soil moisture thresholds: Open valve when moisture drops below setpoint (e.g., 25% VWC). Close when target reached (e.g., 35% VWC). Simple and reliable.

ET-based scheduling: Calculate daily water deficit from temperature, humidity, solar radiation. Irrigate to replace deficit. More complex but handles varying crop stages.

Multi-zone optimization: Different crop types or soil conditions need different schedules. LoRaWAN allows individual zone control across large areas without trenching control wires.

Typical Applications

Vineyards: Controlled water stress during certain growth stages improves grape quality (higher sugar concentration). Soil moisture sensors at multiple depths prevent over/under watering.

Orchards: Drip irrigation systems with soil moisture monitoring. Large areas (50+ hectares) benefit from LoRaWAN's range - no need for cellular coverage or trenched control cables.

Row crops: Center pivot or linear move systems can integrate LoRaWAN soil moisture sensors to trigger automatic start/stop based on field conditions.

Greenhouses: Multiple irrigation zones with individual moisture/temperature monitoring. Automated fertigation control based on plant growth stages.

Hardware Selection

Soil moisture sensors:

Capacitive sensors work well for most agricultural applications, providing reliable volumetric water content measurements at reasonable cost. TDR sensors offer higher precision needed for research applications or situations requiring laboratory-grade accuracy. Place sensors at crop root depth—typically 30-60cm depending on crop type—where they actually measure water availability to the plant.

Valve controllers:

Latching solenoid valves draw power only during state changes, making them ideal for battery-powered installations. Non-latching valves require continuous power to remain open, consuming significantly more energy. LoRaWAN valve controllers integrate wireless communication with valve actuation, eliminating the need for control wire trenching across fields.

LoRaWAN gateway:

Indoor gateways work when fields lie within moderate range. Outdoor gateways with elevated antennas extend coverage significantly, often covering entire farms from a single installation point. Actual range depends on terrain topography, crop canopy density, and antenna placement—field testing verifies coverage before full deployment.

Common Mistakes

Wrong sensor placement: Sensors too close to drip emitters or sprinkler heads give misleading readings. Place between emitters where roots actually grow.

Single-point sensing: One sensor per 5+ hectare field is useless. Soil variability means you need multiple sensors to understand actual conditions.

No flow metering: You need to know how much water actually got delivered. Broken pipes, clogged emitters, or valve failures are invisible without flow meters.

What I Provide

Services:

- Irrigation system design and sensor placement strategy

- Hardware specification based on crop type, soil conditions, and budget

- LoRaWAN network planning and coverage analysis

- Control algorithm development (threshold-based, ET-based, or hybrid)

- Data pipeline setup and visualization dashboards

- Alert configuration for system failures and anomalies

- Integration with existing irrigation infrastructure

You own everything:

- Complete source code for control algorithms and automation logic

- Self-hosted infrastructure (network server, database, dashboards)

- All system configuration and installation documentation

- Sensor calibration procedures and maintenance guidelines

- No ongoing licensing fees or vendor dependencies

I work with whatever irrigation infrastructure you already have—upgrading fixed schedules to sensor-based control, or designing new installations from scratch. The goal is water savings and better crop outcomes, not pushing specific hardware brands.

Ready to Get Started?

Get expert guidance on implementing LoRaWAN solutions for your organization.

Let's Talk