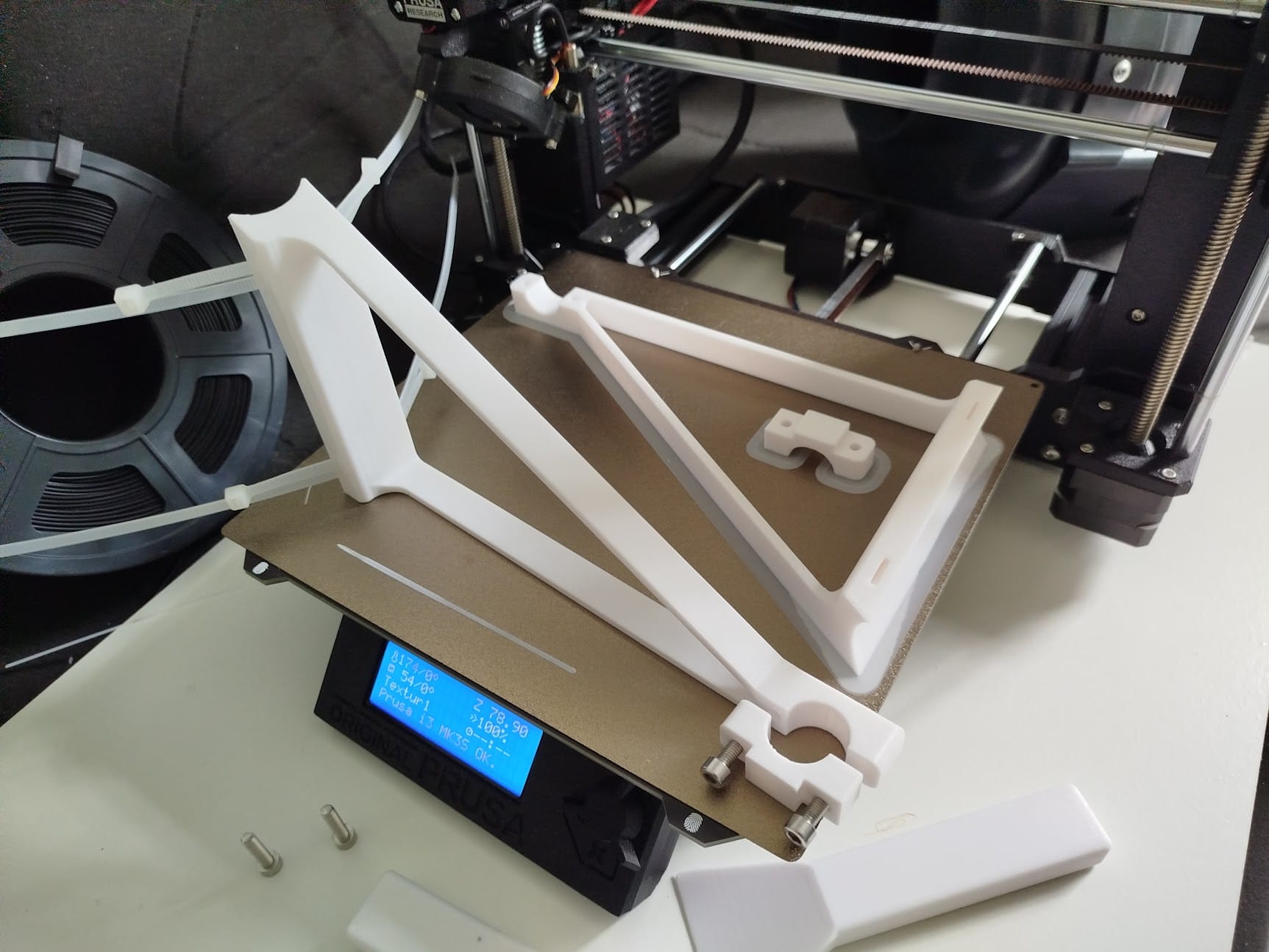

3D Printed Mounts for LoRaWAN Sensors

Why 3D Print Mounts

Commercial weather station mounts cost significantly more than 3D printed alternatives and never fit exactly right. Custom 3D printed mounts are lighter, fit perfectly, and you can iterate the design in hours instead of waiting weeks for a supplier to manufacture and ship standard brackets.

Common scenario: You need to mount an anemometer on 32mm galvanized pipe at a specific angle to clear a solar panel. No commercial bracket exists for that combination. Design it in FreeCAD, print overnight in ASA plastic, install the next day. The material cost is a fraction of commercial alternatives.

What I Design and Print

Sensor mounts:

Weather station pole mounts accommodate standard pipe sizes from 25-60mm diameter, fitting most utility poles and agricultural infrastructure. Wall and ceiling brackets suit indoor gateways where aesthetics and cable management matter. Adjustable angle mounts for anemometers allow precise positioning to clear obstacles like solar panels or roof edges. Multi-sensor platforms combine temperature, humidity, and pressure sensors in single weatherproof housings, reducing installation complexity.

Gateway enclosures:

Custom-fitted cases for various gateway models—SenseCAP, Dragino, and others—protect electronics while allowing antenna mounting and heat dissipation. Waterproof outdoor housings include integrated cable glands preventing moisture ingress. Battery compartments with ventilation slots prevent hydrogen buildup from lead-acid batteries while keeping electronics dry. Mounting brackets handle specific installation scenarios like wall mounting, pole attachment, or DIN rail installation.

Cable management:

Clips and guides route antenna cables cleanly along poles or building surfaces, preventing wind damage and improving aesthetics. Strain relief components protect cable connections from repeated flexing during wind events. Weatherproof cable entry and exit solutions seal enclosures while allowing cables through, maintaining IP ratings without expensive commercial glands.

Material Selection

PLA:

Indoor only for standard PLA. Cheap and easy to print, but deforms in summer heat above 50°C. White PLA+ can stand the test of time in moderate climates where temperatures stay below 40°C. Use for prototyping or indoor brackets where cost and ease of printing matter more than weather resistance.

PETG:

Best general-purpose outdoor material. Weather resistant, UV stable, and strong—my go-to for most outdoor mounts. Balances printability with durability. Handles temperature extremes better than PLA without the printing difficulty of ASA. Costs more than PLA but remains affordable for small-batch production.

ASA:

Better UV resistance than PETG. Survives direct sunlight for years without significant degradation. Requires enclosed printer due to styrene fumes during printing. Use for permanent outdoor installations where long-term UV exposure is unavoidable. Slightly more expensive than PETG and harder to print, but worth it for applications demanding maximum weather resistance.

TPU:

Flexible rubber-like material. Works for gaskets, vibration dampening, and protective bumpers. Slow to print compared to rigid materials but useful for specific applications where flexibility prevents damage or improves sealing. More expensive than rigid filaments.

ABS:

Impact resistant with high temperature tolerance. Warps easily during printing—PETG or ASA are usually better choices offering similar properties with easier printing. Only use ABS when impact resistance outweighs printing difficulty.

Why It Makes Sense

Fast iteration: Design flaw discovered during test fit? Fix in CAD, print updated version overnight. Compare to ordering from supplier: 3-4 weeks lead time minimum.

Custom fit: Every installation is different. Pipe diameters, mounting angles, clearance requirements vary. 3D printing handles one-off requirements that injection molding can't justify.

Lightweight: Printed parts use 20-50% less material than machined alternatives. Matters for pole-mounted sensors where weight affects stability.

Complex geometry: Can print internal channels for cable routing, integrated cable clips, threaded inserts. Traditional manufacturing requires assembly of multiple parts.

Limitations

Not for everything: High mechanical stress applications need aluminum or steel. 3D printing is for brackets, housings, adapters - not structural components.

Surface finish: Layer lines visible. Not as smooth as injection molded parts. Functional vs cosmetic.

Production quantity: Makes sense for 1-100 units. Beyond that, injection molding becomes cheaper per unit.

UV degradation:

Even ASA degrades eventually in direct sunlight. Outdoor parts last several years before needing replacement—then you simply reprint them at minimal cost rather than sourcing expensive commercial replacements.

Typical Projects

Weather station mounts: Standard utility poles (25-60mm diameter), building facades, agricultural infrastructure. Include cable routing channels and adjustable angles.

Gateway housings: Custom enclosures for various gateway models with antenna mounting, cable glands, ventilation slots. PETG or ASA depending on UV exposure.

Sensor packaging: Weatherproof housings for custom electronics. Design includes mounting brackets, battery access doors, cable entries.

Design Process

1. Spec gathering: Photos of installation site, measurements of mounting surface/pipe, clearance requirements, environmental conditions (UV exposure, temperature extremes).

2. CAD design: Model in FreeCAD (open source) or Fusion 360. Design for printability - avoid overhangs >45°, include print-in-place hinges where useful.

3. Test print: First version almost always needs tweaks. Test fit, identify issues, revise. Usually 2-3 iterations to get perfect fit.

4. Final production: Once design proven, print production quantities. Typical: 1-10 units per project.

5. Files delivered: You get STL files. Print yourself or use local print service. Design is yours to modify/reprint.

Print Settings That Matter

Layer height: 0.2mm standard. 0.3mm for faster rough parts. 0.1mm for fine details (rarely needed for mounts).

Infill: 20% sufficient for most brackets. 40% for high-stress applications. 100% infill rarely needed - wastes material and time.

Perimeters: 3-4 walls minimum for outdoor parts. Strength comes from perimeters more than infill.

Supports: Design to minimize support material. Wasted plastic and rough surface finish. Orient parts cleverly during slicing.

What I Provide

Services:

- Custom mount and enclosure design for specific installation requirements

- Material selection guidance based on environmental conditions and durability needs

- CAD modeling optimized for 3D printing (minimizing supports, ensuring printability)

- Print settings recommendations for different materials and printers

- Design iteration based on test fit feedback

- Installation planning and hardware specification

You own everything:

- Complete CAD files (STEP format—editable in any CAD software)

- STL files ready to slice and print

- Print settings documentation (layer height, infill, supports)

- Installation instructions and hardware specifications

- Full rights to modify, reprint, or manufacture designs

I design the parts—you handle printing and production. Print yourself if you have equipment, or use local print services. This keeps costs minimal and eliminates international shipping delays. You're not dependent on me for replacements or modifications.

Ready to Get Started?

Get expert guidance on implementing LoRaWAN solutions for your organization.

Let's Talk